Heat Pumps

We can install Air Source and Ground Source heat pumps that can replace gas, oil & LPG boilers.

Heat Pumps

Known as the “magic trick” of the renewable industry, Heat Pumps are now the accepted replacement for gas, oil and LPG boilers. They will replace gas boilers on new developments from 2025 when new gas connections are outlawed, and will be the only heating appliance solution when fossil fuel appliances are banned for domestic use (currently penned for 2035).

We install Air Source & Ground Source heat pumps...

Heat pumps are already a hugely popular replacement for oil and LPG boilers in rural areas, where clients benefit from being able to remove external fuel storage tanks and highly polluting boilers, together with the need for fuel deliveries. They are a fantastic way of heating your property in a sustainable and low carbon way. Thanks to innovative technology they are able to heat up hot water systems and radiators instead of having to rely on fossil fuel boilers.

This technology originated in Scandinavian countries many decades ago where they have much lower ambient temperatures than we do, so don’t be under the impression that this is an un-tried concept. It is a tried and proven technology. In fact, we already have tens of thousands of Heat Pumps installed in the UK already.

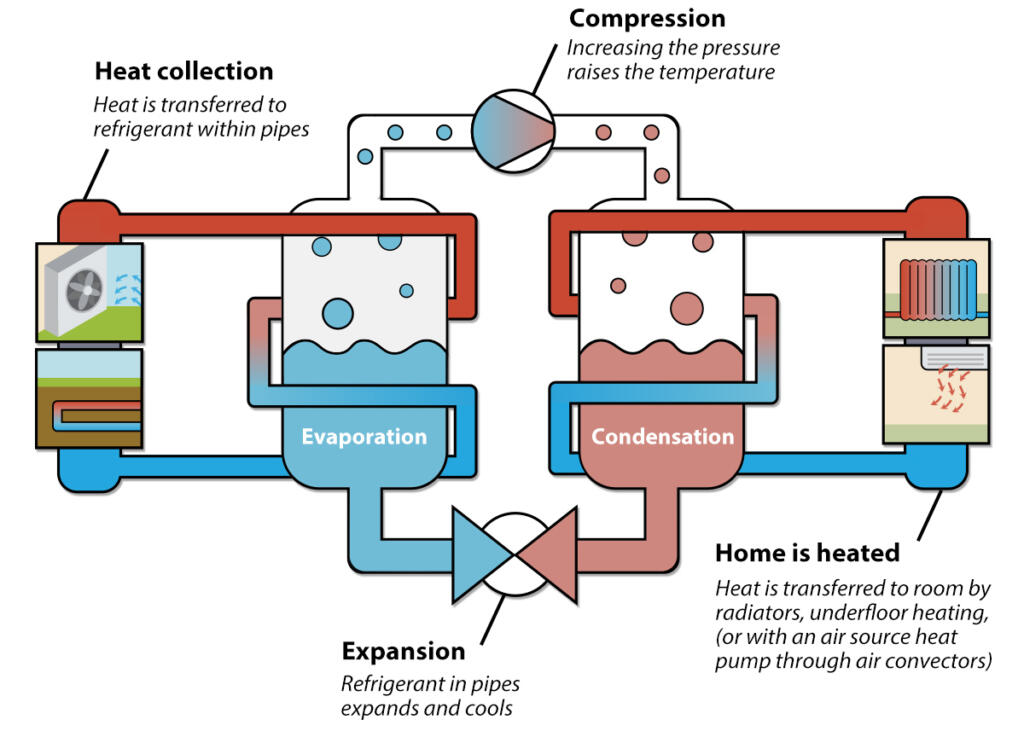

How do Heat Pumps work?

Heat Pumps take low-temperature heat from the air (in the case of ASHPs) or the ground (in the case of GSHPs). By passing this low-temperature heat through a refrigerant fluid and a compressor within the unit, the low temperature heat is compressed and amplified to temperatures of up to 55ºC. This high-temperature heat is then sent through the radiator and hot water system as it would do with a conventional boiler.

The system can deliver these high temperatures even when operating in ambient climates as cold as -20ºC. In simple terms, the colder the ambient temperature, the more we need to compress that air to create our desired temperature.

This may sound completely mad, but we have probably all experienced this for ourselves. If you have ever pumped up a bicycle tyre, you’ll remember the end of the pump starts gets hotter as you squeeze more and more pressure into the tyre – it is exactly the same principle and is a simple law of physics… when you squeeze air, you create heat as a by-product.

Air Source or Ground Source Heat Pumps?

Air source and Ground Source Heat Pumps are essentially the same technology. What differs is where they collect their low temperate heat from

Air Source Heat Pumps

Air source involves installation of a heat pump unit hat sits outside the property. The unit contains everything required to lift (compress) and deliver heated water into the property for space heating and hot water. For properties where internal space is at a premium, air source can be the perfect solution.

Air source collects its low temperature energy from the air, so depending on the time of year and the ambient temperature, the efficiency of the unit will rise and fall. As already noted, the air source heat pumps we install will operate in temperatures as low as -20c. So rest assured you will always be warm.

We install Mitsubishi air source Heat Pumps by choice. Their performance is measured on an annual average efficiency, known as an SCOP ( seasonal coefficient of performance). The Misubishi range achieves as annual SCOP of arround 1:3.5, meaning for that every unit of electric the ubit consumes you get an average of 3.5 units of heat. It is this super – efficient operation that is so exciting!

From the running cost point of view, running a heat pump is rarely more expensive than heating with fossil fuel, especially considering that technologies like Solar PV can provide an element of free electricity to help power the unit. Supporting a heating system with Solar PV is simply impossible using a fossil fuel boiler.

Ground Source Heat Pumps ‑ Horizontal Loops

Linear pipes are laid in the ground using conventional excavation or mechanical plough or cutting machines.

Pipes are laid at a depth of 900mm-1m in the ground. This is below the Permafrost depth. The Permafrost is the point in the ground where freezing can occur in a severe Winter. So being below this level ensures we are collecting temperatures from 0C to +10C, but not colder. Loops have a circa 2 metre separation from each other, with a 1 metre separation between each flow and return pipe. This ensures that we are able to collect low-temperature heat-energy at a slower rate than nature replenishes it, meaning an endless supply of low-temperature heat-energy exists for use.

The ground Loops are filled with a Heat Transfer fluid which has an Anti-freeze additive to ensure low-temperature heat-energy can be transferred back to the Internal Heat Pump unit regardless of Winter conditions.

Horizontal Loops are suitable for farm sites. The loops sit below ploughing depth. Land can continue to be used for farming post-installation.

Ground loop lengths are designed / sized on a site-by-site basis to ensure that we are collecting the correct volume of low temperature heat-energy to feed the Heat Pump unit for the property’s requirements.

WE DO NOT USE SLINKY’S. These are a coiled version of our linear pipe-work. They are used/were designed for sites where clients do not have the required land for linear loops. Slinky’s are, in our opinion, a flawed solution. Coiling the pipe in the ground can result in the energy in the ground from being used faster than nature (sun and rain) can recharge it. The result is often areas of frost on the ground and sub-zero temperatures of heat-energy being sent to the Heat Pump. This results in a loss of efficiency, increased running costs and Heat-pump fatigue.

We adopt a simple technical guide line one installation of horizontal Ground loops: if you do not have suitable land-space you are not having horizontal loops! It is as simple as that. Air Source Heat Pumps or Vertical Bore Hole Ground Source should be considered instead.

It is typical for a Ground Loop system to contain many loops. The Ground Loops are terminated in an external Manifold. This is a chamber that sits in the ground and allows for connection of multiple loops. Connections are Fusion welded, not Mechanical. These plastic-to-plastic welds cannot leak.

We then run a pair of larger diameter pipes (known as the Master Header Pipes) below ground towards the property for ultimate connection to the Heat Pump unit.

What land do I need for Horizontal loops?

Ground Loop lengths are calculated and installed based on the Heat Load requirements of the site. To enable correct access to and around the site, we regardless recommend a minimum of 1acre be available. We also recommend a paddock is used.

Due to the excavation and heavy-plant nature of the work we would not recommend installing ground loops to formal garden areas. We do not recommend installation to wooded or orchard areas, as installing loops can often interfere with lateral or secondary tree-roots. As trees grow there is also risk of roots interfering with ground loops.

Ground Source Heat Pumps – Vertical Bore Hole Loops (VBHL)

Vertical Bore Hole loops are the Premium installation method for Ground Collection loops. Unlike Horizontal Loops, a Vertical Bore Hole Installation involves a number of Bore Holes to drilled to depths of up to 150m into the ground (500-feet down). Low-temperature heat-energy loops are then lowered into the bore-holes. The bore holes are then filled with a thermal grout and capped off at the surface.

As with Horizontal loop installations, it is common for multiple loops to be drilled / installed to a site, with the pipework being taken below ground by our Groundworks teams to an in-ground man fold where they are fusion-joined. A pair of master header pipes then continuer below ground back to the property where the heat pump unit is sited.

VBHL has a number of benefits over Horizontal Loop ground installations.

Firstly, they can be installed in much smaller land ownership. It is common to install to driveways or gardens. Aside from access by the drilling rig and associated plant, physical excavation and disruption is reduced.

Secondly, the temperature in the ground at depths of 30m and lower is a fairly constant 10-12C, regardless of winter ambient temperatures. At those depths we are simply too low in the ground for seasonal effects to impact temperature in the ground. So, unlike Horizontal Loop heat-energy collection that ranges from 0C to 10C, with VBHL installations we have a constant 10-12C of latent heat beneath our feet that we can tap into, 365 days per annum.

Access

Access requirements exist for both forms of Ground Source Heat Energy Collection. If site can be accessed by a tractor it is likely we can access with out plant. Contact us to discuss requirements in more detail, where we can advise of what may or may not be feasible.